Elastyczne rozwiązania systemowe dla e-mobilności

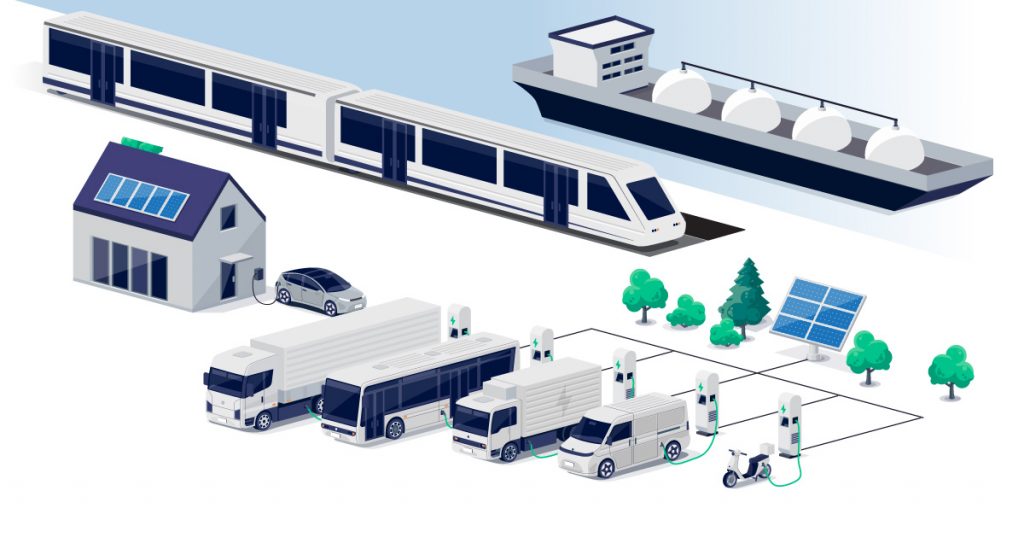

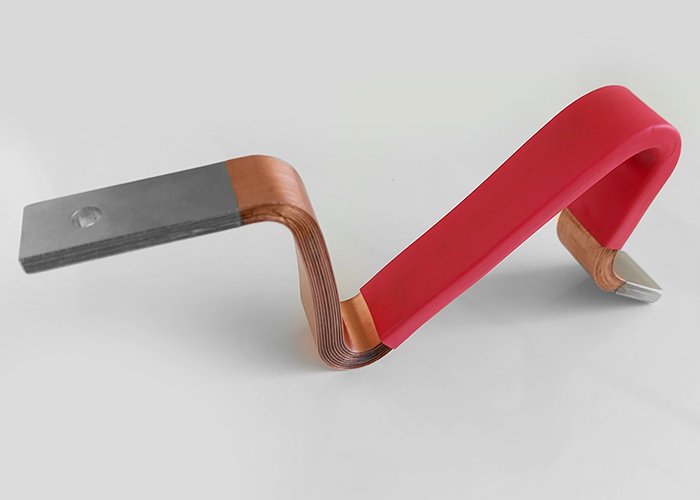

E-mobilność oznacza dla nas dzisiaj mobilne zastosowania koncepcji przesyłu energii i uziemienia. EMS opracowuje i produkuje od produkcji prototypowej do małych serii, indywidualne i innowacyjne rozwiązania dla E-mobilność. Tutaj wyzwaniem jest głównie połączenie wagi, nośności prądowej, galwanizacji, izolacji i przestrzeni instalacyjnej oraz symbiotyczna integracja z zespołami naszych klientów. Analizując sytuację instalacji i jej warunki środowiskowe, współpracujemy z Tobą, aby opracować właściwe komponenty dla Twojej aplikacji, zawsze szyte na wymiar.

Stosowana technologia połączeń

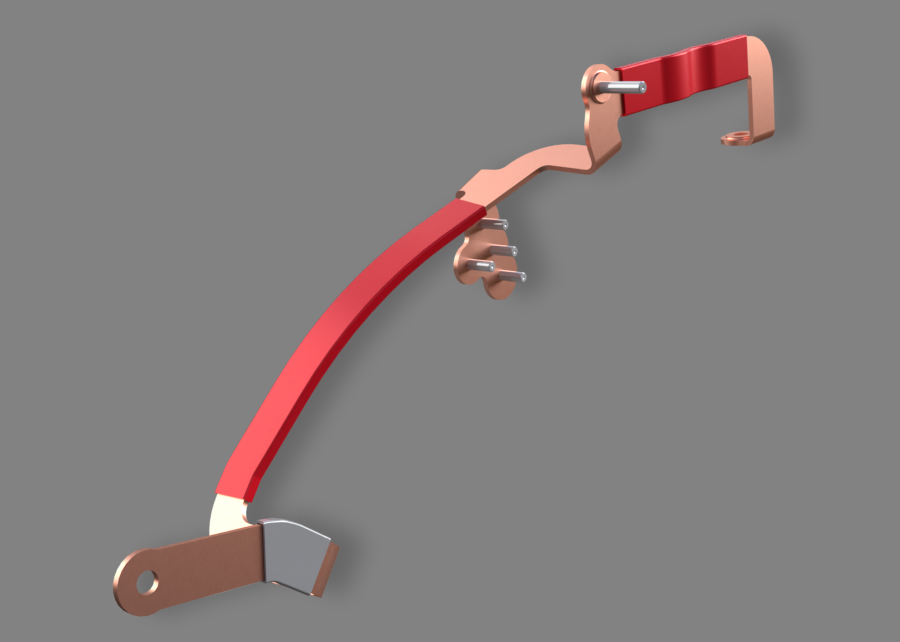

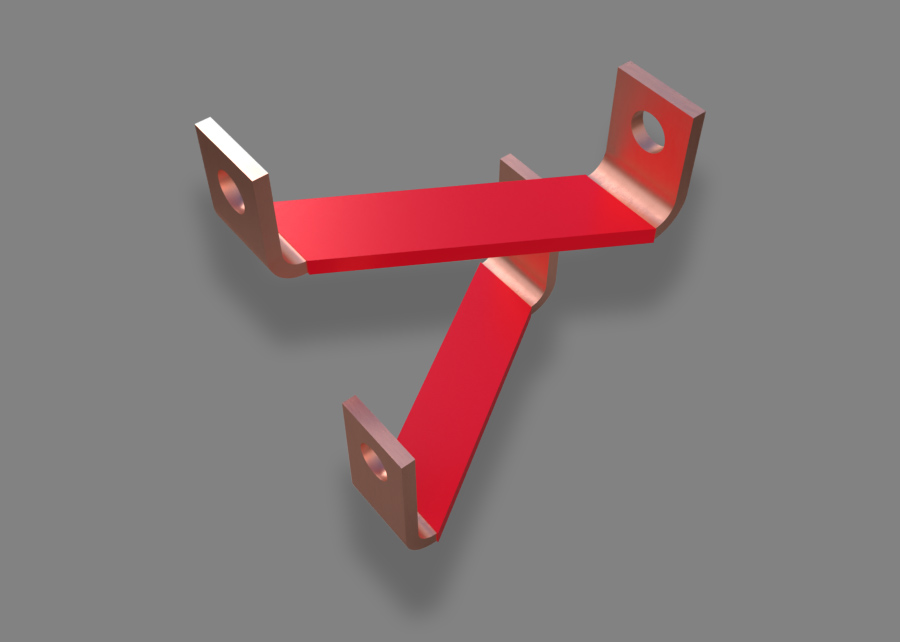

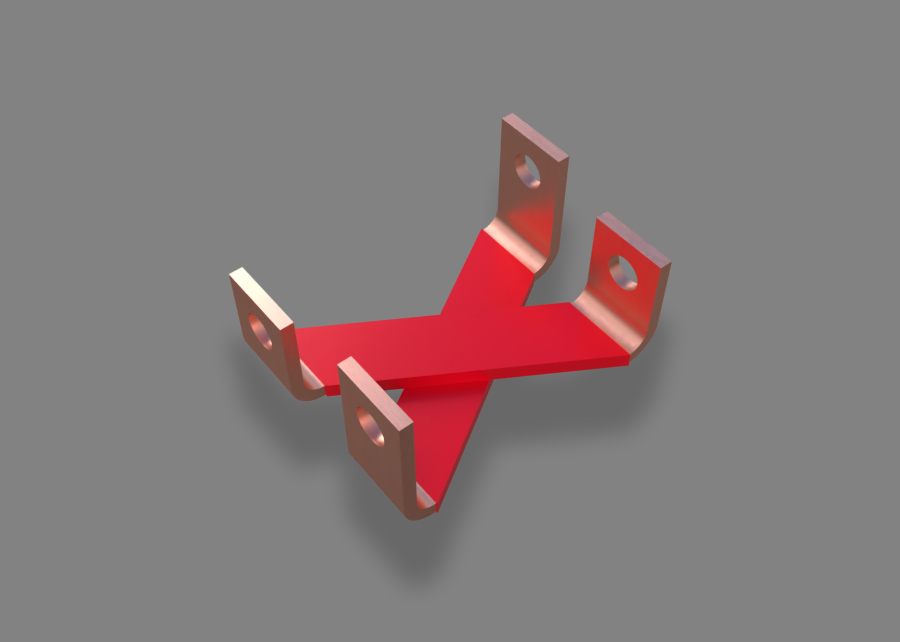

Elastyczne złącza baterii dla e-mobilności

- Pojazdy przemysłu motoryzacyjnego

- Pojazdy użytkowe, takie jak wózki widłowe i zamiatarki

- Sprzęt sportowy, taki jak deski surfingowe

Bez względu na to, jaki pojazd aktualnie opracowujesz, pomagamy w realizacji Twoich aplikacji z napędem akumulatorowo-elektrycznym. We współpracy z naszymi klientami opracowujemy rozwiązania wyznaczające trendy, takie jak elastyczne taśmy rozprężne, wysoce elastyczne żyły lub zespoły do mobilności akumulatorowo-elektrycznej.

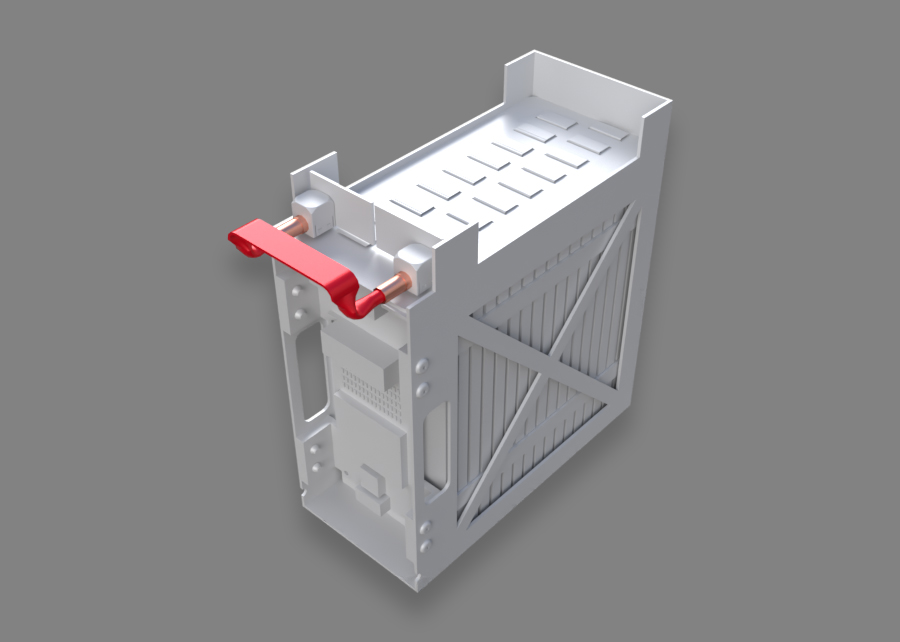

Mobilność wodoru

- Przemysł motoryzacyjny

- Przemysł kolejowy i żeglugowy

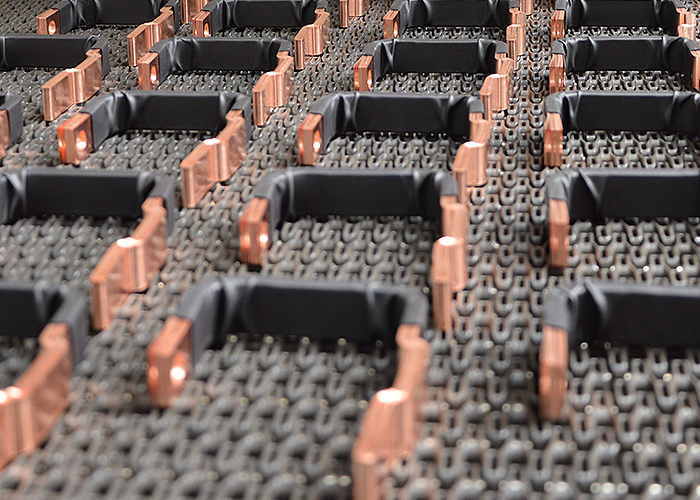

Mobilność wodorowa jest jasną alternatywą, aby ograniczyć emisję CO₂. Wodór przechowywany w pojeździe jest przekształcany w energię elektryczną za pomocą ogniwa paliwowego, które z kolei napędza silnik elektryczny. Najważniejszymi zaletami aktualnych pojazdów elektrycznych są szybkie tankowanie i duża moc. Ogniwa paliwowe zasilane wodorem są obecnie wykorzystywane w przemyśle samochodowym, ciężarowym, morskim i kolejowym. Również w tym przypadku nasze komponenty łączą przenoszenie mocy w najbardziej efektywny sposób. Zgłoś się do nas!

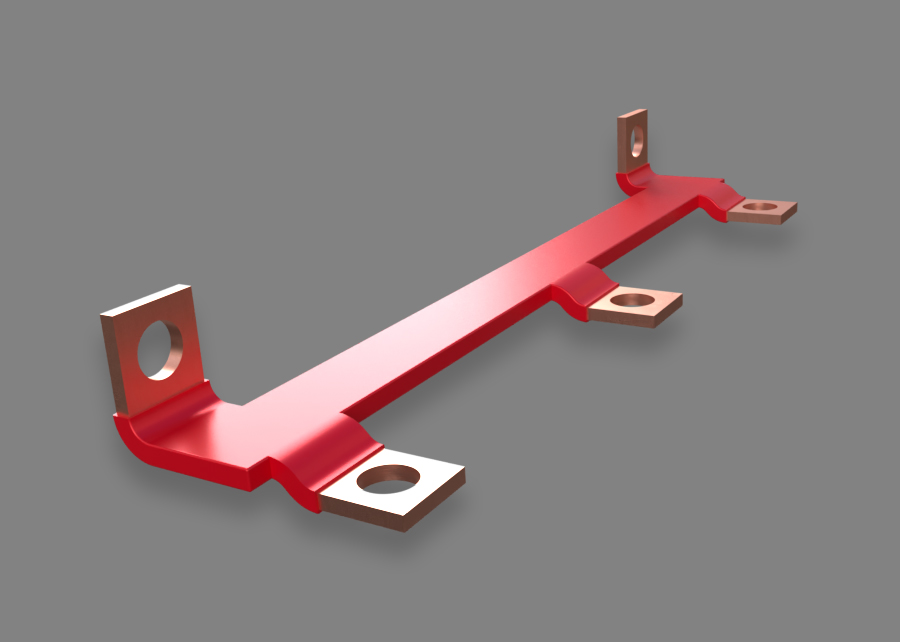

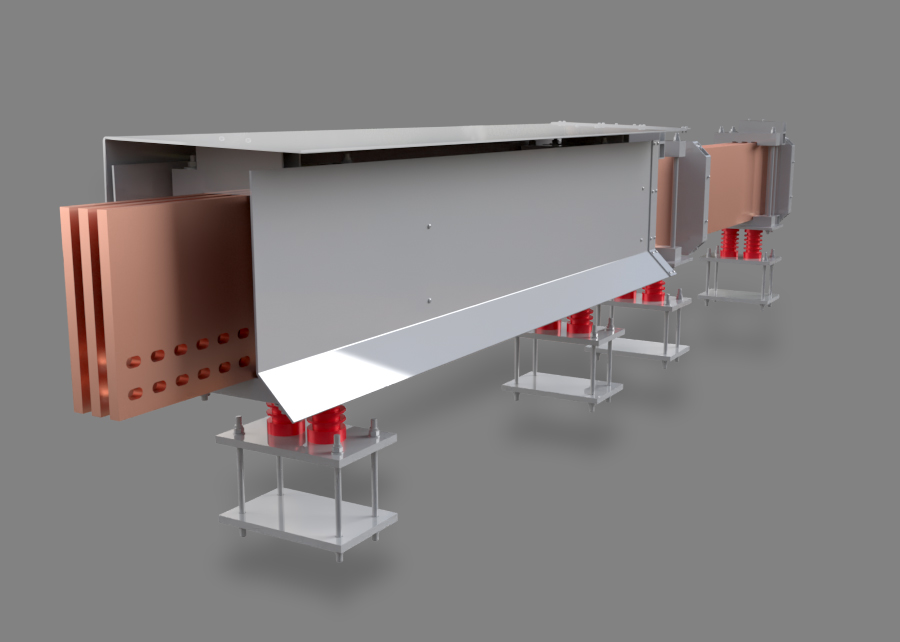

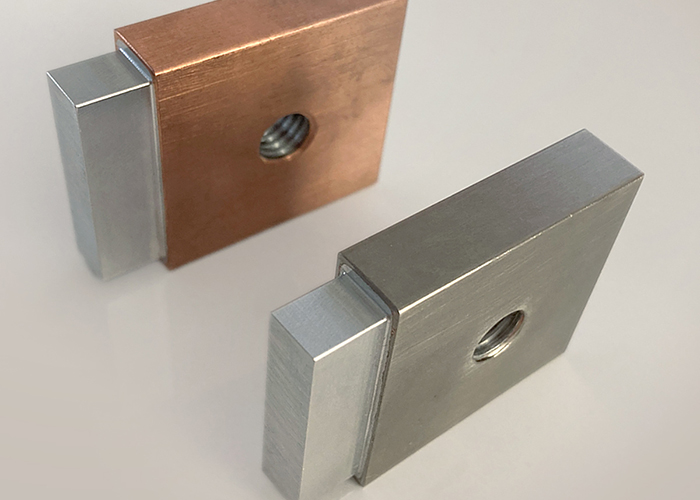

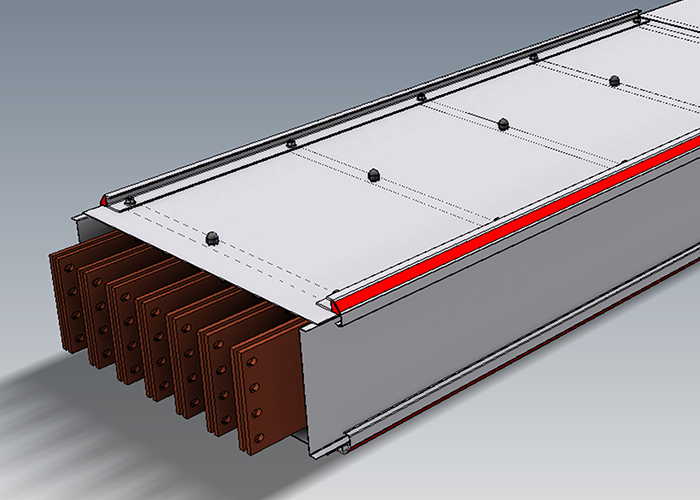

Koncepcje uziemienia dla technologii kolejowej

W technologii kolejowej komponenty aluminiowe, takie jak nadwozia wagonów i kontenery, muszą być uziemione, aby zagwarantować bezawaryjny powrót prądu roboczego. Pasy uziemiające EMS służą jako element łączący dla kabli uziemiających do uziemienia komponentów aluminiowych. Szczególną cechą naszych pasków uziemiających CoppAl® jest powłoka odporna na zgrzewanie. Oznacza to, że paski uziemiające EMS mogą być spawane bezpośrednio do elementów aluminiowych w celu utworzenia dodatniego połączenia. W ten sposób można trwale zmniejszyć rezystancję przejścia. Nasze paski uziemiające CoppAl® są wykonane z materiału kompozytowego (CuAL lub Cuponal) i optymalnie łączą wysoce przewodzącą miedź z niską wagą aluminium.

Elastyczne rozwiązania dla e-mobilności

EMS oznacza usługi holistyczne

W ścisłej współpracy z Państwem systematycznie rozwijamy projekty i sprawnie je wdrażamy.

Koncentrujemy się na optymalizacji funkcjonalności, a także aspektach infrastrukturalnych, produkcyjnych i ekonomicznych. Rezultatem są indywidualne rozwiązania, które są ukierunkowane na efektywność ekonomiczną i spełniają wymagania klienta w najdrobniejszych szczegółach.

Podstawowe kompetencje EMS

Wszystko z jednego źródła

Niezawodność, jakość i zrównoważony rozwój to nasze dewizy. Jako strategiczny partner jesteśmy pierwszym wyborem dla naszych klientów.

Inżynieria rozwiązań systemowych

Wspieramy Państwa w technicznej Inżynierii rozwiązań systemowych dla indywidualnych wymagań. Zapraszamy do kontaktu!

Montaż podzespołów

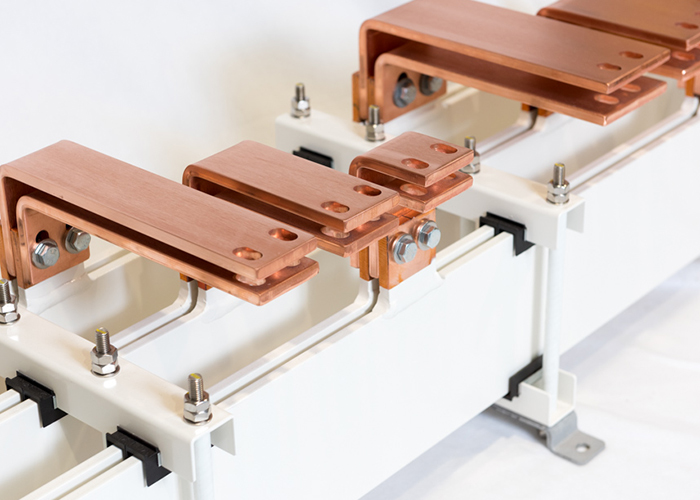

W razie potrzeby szyny zbiorcze mogą być również montowane na miejscu u klienta lub możemy przejąć wstępny montaż Zespoły ex works.

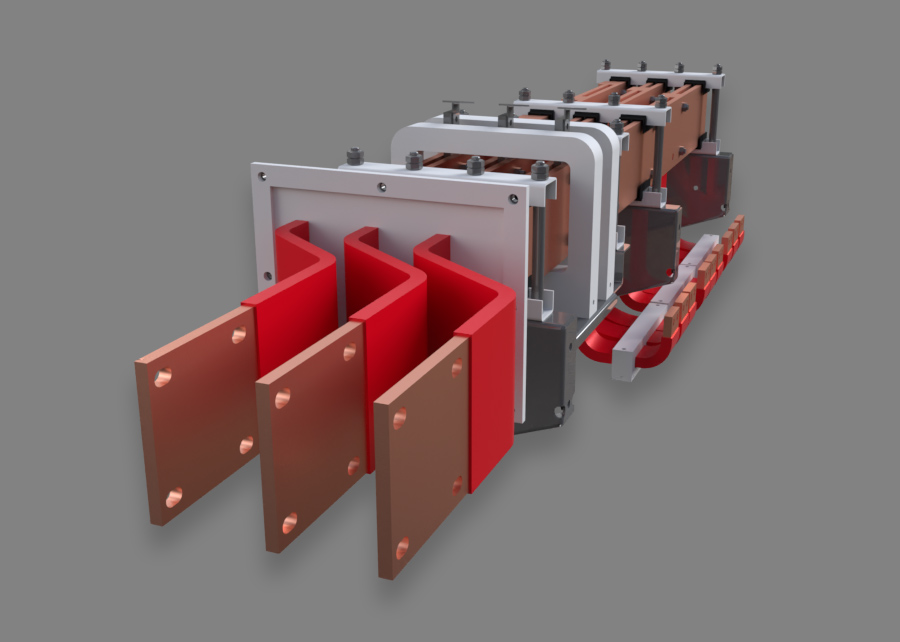

Produkcja technologii połączeń wysokoprądowych

Maksymalna precyzja dzięki know-how i nowoczesnym maszynom – nasza produkcja profesjonalnie wdraża również złożone rozwiązania systemowe.

Wysyłka i logistyka na całym świecie

Gotowe zamówienia szyn zbiorczych łączymy w elastyczne jednostki wysyłkowe zgodnie ze specyfikacją klienta.

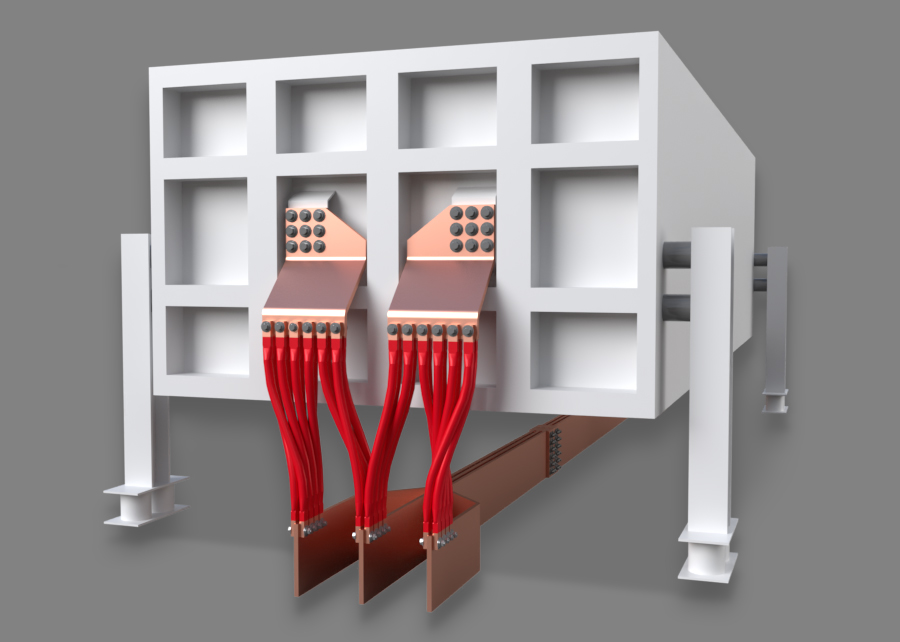

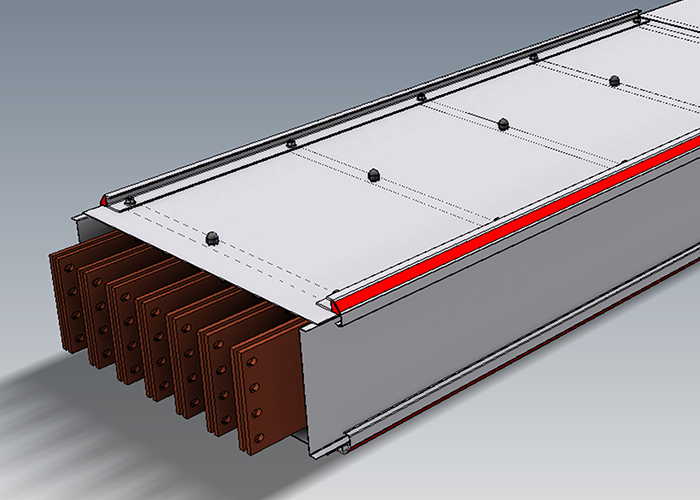

Elastyczne połączenia prądowe dla większej e-mobilności

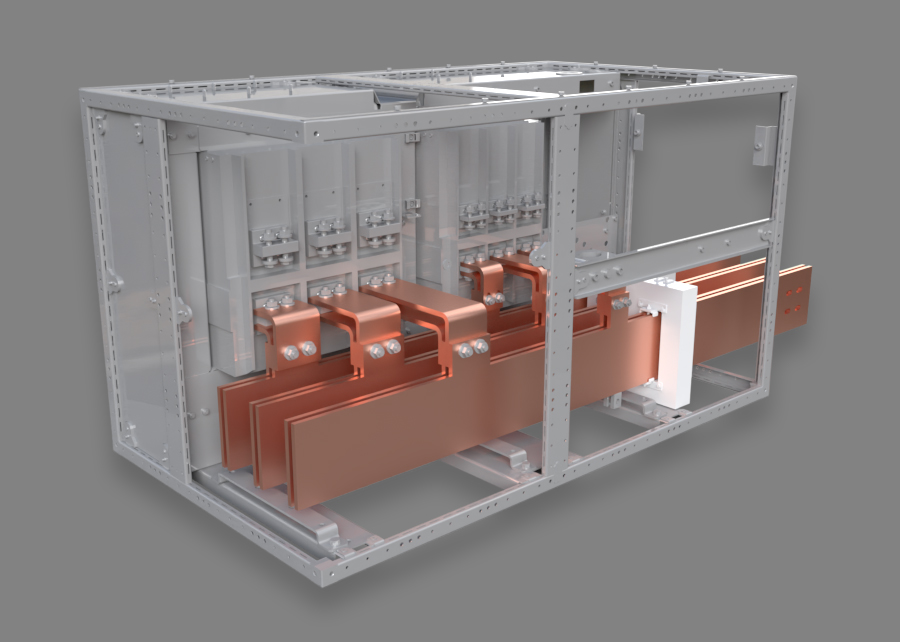

W EMS mamy wieloletnie doświadczenie w rozwoju, produkcji i montażu innowacyjnych systemów szyn zbiorczych.

Nasze elastyczne połączenia prądowe są używane jako kompensacja drgań i wibracji w różnych pojazdach.

“Wspólnie z Tobą, jako partnerem strategicznym, opracowujemy przyszłościowe rozwiązania dla mobilności jutra!”

Nasze usługi

Konsultacje

+ Indywidualna oferta

+ Szczegółowy pomiar

+ Gwarancje

+ Warunki umowy

+ Optymalizacja kosztów

+ Proces zatwierdzania części do produkcji PPAP

+ Wytyczne APQP

+ Audyty

Rozwój

+ Zarządzanie projektami

+ Rozwój techniczny

+ Projekt przekroju poprzecznego

+ Obliczenia pola magnetycznego

+ Przygotowanie projektu i rysunków

+ Kontrola wykonalności

Wykonane na wymiar

+ Produkcja i wytwarzanie

+ Elastyczne szyny zbiorcze

+ Masywne szyny prądowe

+ Płaskie szyny zbiorcze

+ Systemy szyn zbiorczych

+ Zespoły szyn zbiorczych

+ Dalsza obróbka

+ Personalizacja

Logistyka

+ Wysyłka na cały świat

+ Wysokiej jakości opakowanie

+ Dostosowane zgodnie ze specyfikacją

+ Niezawodność i dostawa na czas

+ Dynamiczna regulacja wydajności

Montaż

+ Montaż na miejscu przez

własne lub specjalne

zespoły montażowe

+ Zarządzanie i wsparcie

przez kompetentnych,

doświadczonych inżynierów

Obsługa posprzedażna

+ Konserwacja

+ Części zamienne

+ Modernizacja

Spotkania online

Zarezerwuj spotkanie konsultacyjne już teraz:

Dennis Borsdorff

T +49 6307 9116-0

M +49 173 7376118

E dborsdorff@ems-power.com

Chcesz otrzymać bezpośrednią ofertę? Skorzystaj z naszego formularza - czekamy na wiadomość od Ciebie!

Odkryj nasze komponenty

Niezależnie od tego, czy potrzebne są masywne szyny zbiorcze wykonane z wysoce przewodzącej czystej miedzi Cu-ETP lub kombinowane rozwiązania naszych komponentów, w naszej produkcji wytwarzamy wszystko, od prostych komponentów po w pełni zmontowane zespoły indywidualnie zgodnie z wymaganiami klienta.